Our Techonology

Nano-Injection Molding

What is Nano-injection Molding?

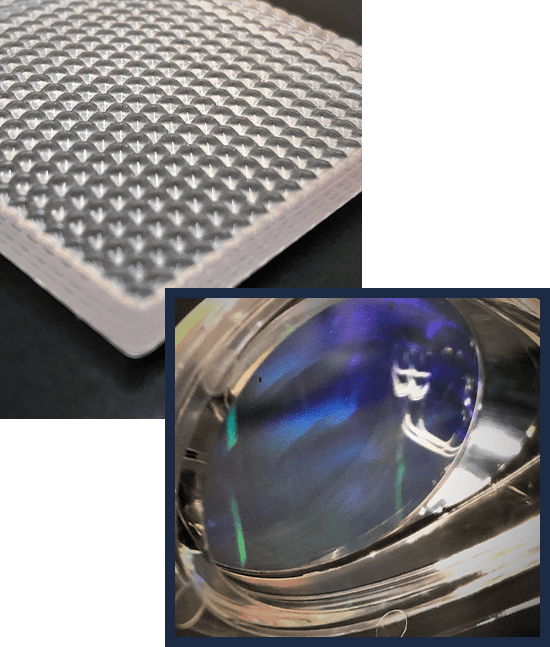

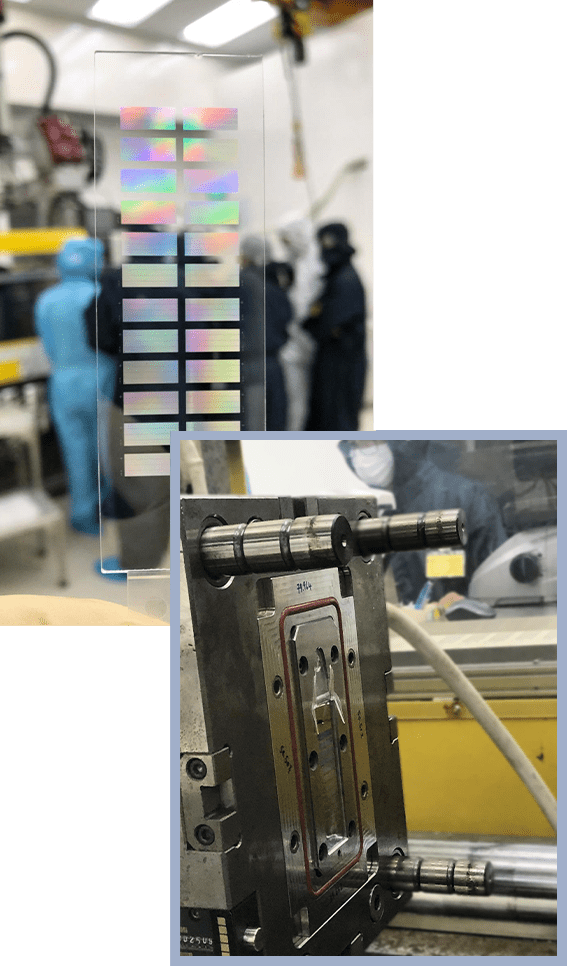

Nano-injection molding is a precision manufacturing process capable of replicating ultra-fine features and patterns (typically below 1 micron) on three-dimensional plastic parts. This advanced molding technique enables the creation of intricate microstructures and nanostructures directly on a polymer’s surface.

Nano-injection molding overcomes the resolution limitations of traditional injection molding and 3D printing. These patterned polymer components are used in various applications, including high-density microarrays for rapid medical diagnostics, precision microlens arrays for advanced optical systems, and complex microfluidic devices for lab-on-a-chip technology.

How Nano-Injection Molding Works

Our nano-injection molding process produces plastic components with micro and nanometer-scale patterned surfaces. This precision is achieved using mold inserts created with advanced techniques like:

Lithography

Plasma Etching

Laser Ablation

Electroforming

Micro-edm

These high-resolution inserts are made from durable hybrid nickel-steel and nickel-shim materials. The molded patterns significantly enhance our plastic products’ optical and mechanical properties. Additional functional and optical coatings can further improve the component performance.

Our facilities

Our state-of-the-art cleanrooms, equipped with cutting-edge nano and micro molding and coating systems, are designed to meet our customers’ stringent requirements.

The Winovus Advantage: Value Proposition of nano-injection molding

Price Competitive

Nano-injection molding offers a cost-effective alternative to nanoimprinted silicon and glass, allowing for integrated functionality on molded plastic parts at a lower price point.

Material Flexibility

We work with a wide range of polymers, including PC, PMMA, COC/COP, PS, ABS, and more, to meet the specific requirements of your application.

Rapid Scalability

We optimise molding manufacturing for high-volume production of 3-D plastic with micro and nanometer structures.

Reduced Complexity

Micro and nanometer scale features improve the functionality of plastic surfaces. Nanoscale injection molding simplifies assembly by integrating added functions into a single plastic component.

Nano-Injection Molding Applications

Examples of Nano-Injection Molding Application and Markets

Microarrays

Microlens Arrays (MLA)

Sensors

Anti-reflective Optics

Microfluidic and Lab-on-a-Chip Devices

Diffractive Optics and Gratings

Virtual & Augmented Reality Optics

Surface Relief Gratings

Medical Equipment & Biotech Optics

Cell-Culture Plasticware

Patterned Petri Dish

Microfilters

Diagnostic Instruments

Superhydrop-hobic Lens Covers

Tailored Nanopatterning Solutions for Your Innovation

From prototypes to production, Winovus delivers cutting-edge nanomanufacturing services. Elevate your project with our expertise.